“Talent wins games, but teamwork and intelligence win championships.” Michael Jordan

This article was originally published on LinkedIn, October 20th 2021

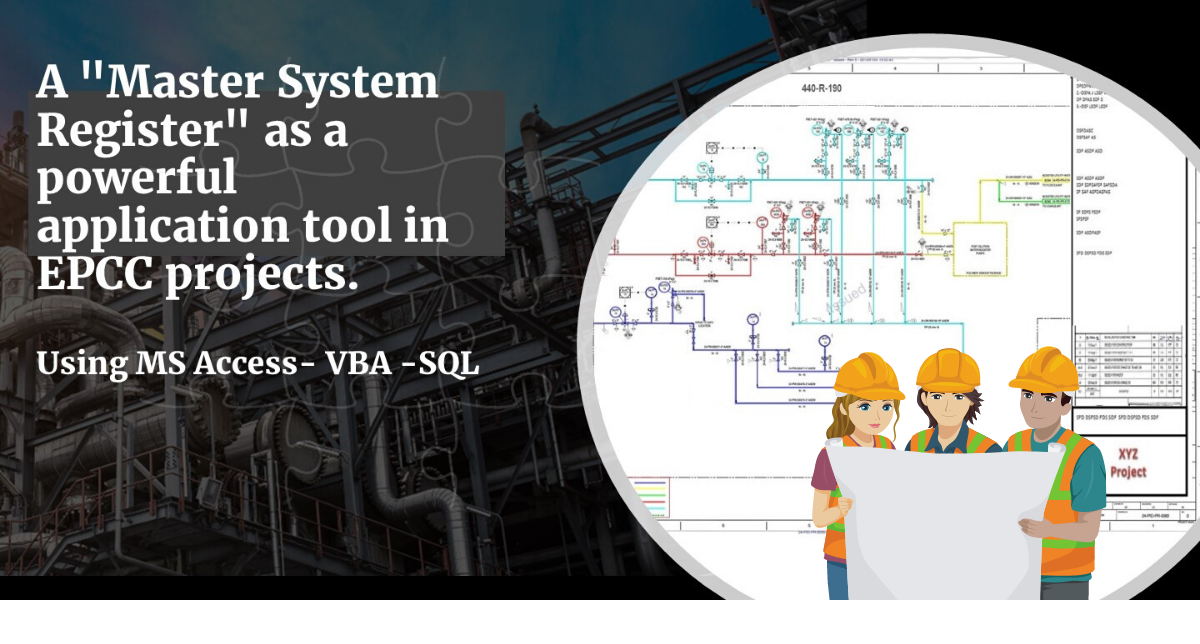

Introduction

Instrument Loop checking is a pre-Commissioning activity initiated after installation of all field instruments. (Field devices I/O via wire ways, junction boxes, and marshaling cabinets to DCS including electrical controls, interface, and final control elements).

In general, complete Instrument Loop Testing objectives include:

· Instrument installation and calibration.

· Instrumentation wiring and interface, communications links to the Control System.

· Loop function and response as configured within design parameters.

· Verification of address, range, alarm, controller action, interlock logic, and ESD functions.

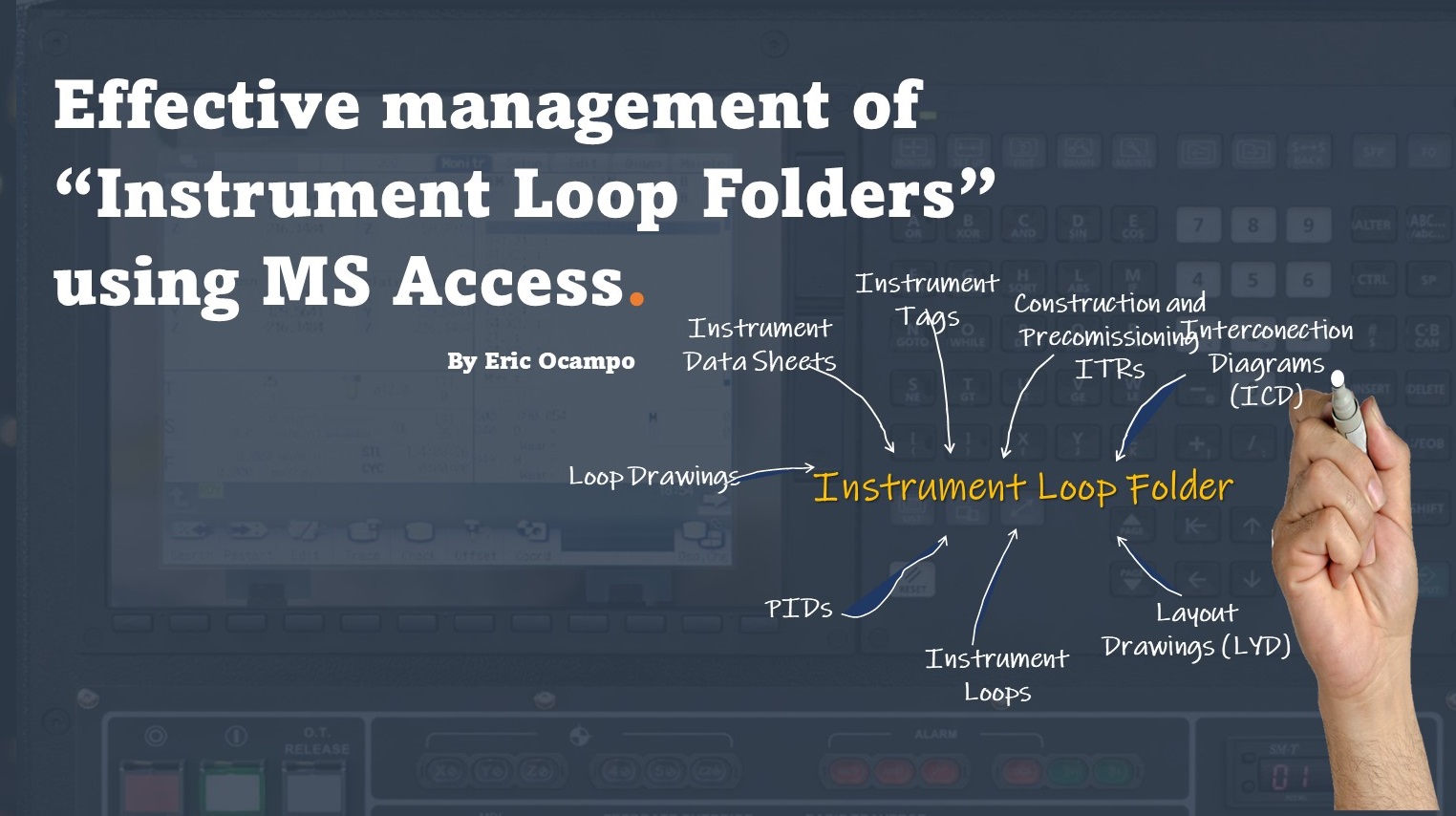

So, before proceeding with the Loop Testing, it is essential to have identified the location, scope, specifications, and readiness of the loop. A common practice in projects is to consolidate the applicable documentation in “Instrument Loop Folders.”

The Instrument loop Folder

Preparation of the instrument loop folders can be a tedious undertaking as the document compilation requires a continuous shifting between folders and applications where those documents reside.

In terms of data and file management, the Loop folders preparation is not that different from Hydrotest Packs (see my LinkedIn article), which consists of collating the different documents from various sources into “packs” or “folders” which identify and support the testing of the components.

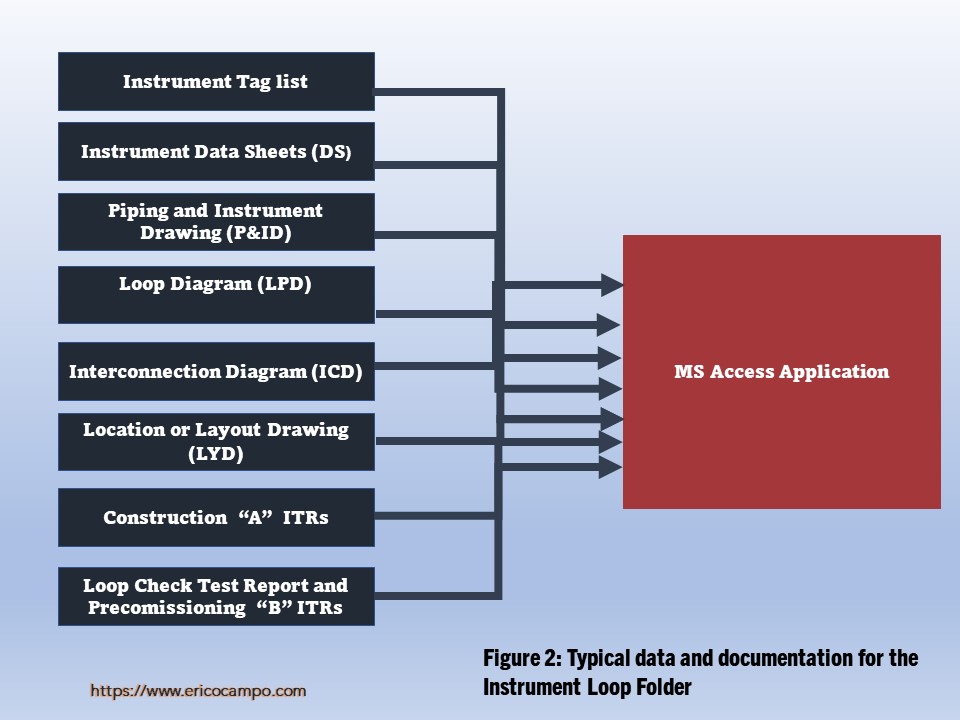

Usually, these are the documents typical of an “Instrument Loop folder”:

· Instrument Tag List

· Instrument Data Sheets (DS)

· Piping and Instrument Drawing (P&ID)

· Loop Diagram (LPD)

· Interconnection Diagram (ICD)

· Location or Layout Drawing

· Construction: “A” ITRs

· Loop Check Test Report and Precomissioning “B” ITRs

In some of the completions teams where I have worked, our team has served as a support in the folder preparation and provided data dump updates for the Instrument Loop progress tracking. But, in other projects, this is a function that resides entirely with the Instrument Precomissioning Team.

Anyway, the present article is about an application I’ve developed in MS Access-VBA – SQL. A relational database approach with interconnected tables in the background and SQL – VBA scripts automating several repetitive and clerical tasks.

Instrument Loop Folder Dashboard

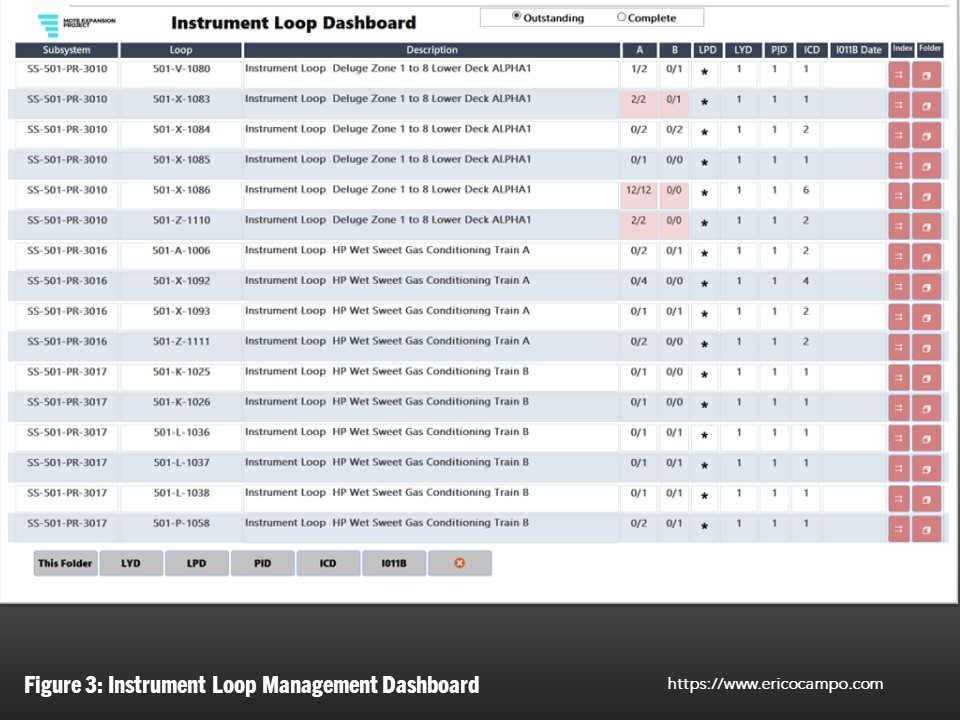

Below is the Instrument Loop Dashboard of the fictitious “Motte” project.

Dashboard columns could be customized per the project requirements, also pop-up entry forms could be configured to filter the instrument loops by System, Area, Milestone, Phase, Contractor, etc.

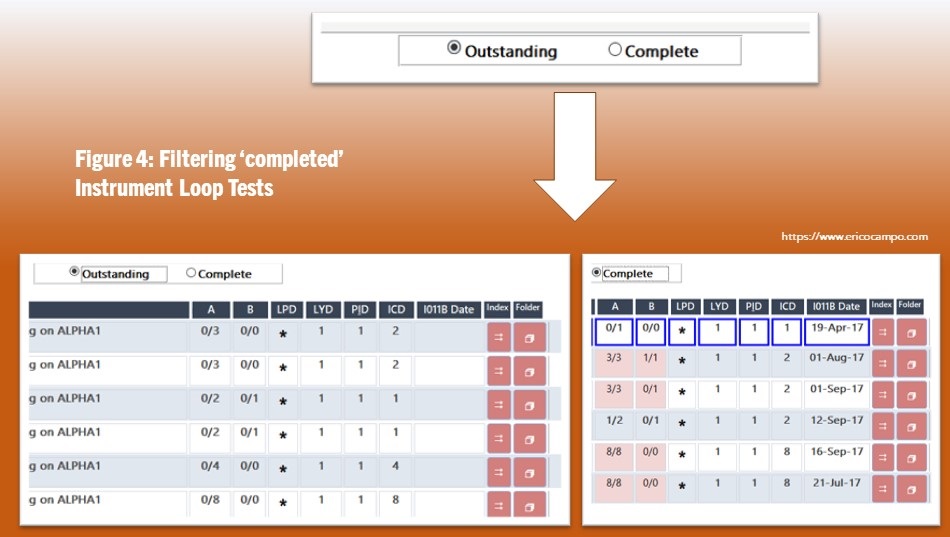

Practical functionality is to quickly see the status of completed and outstanding loop tests by querying the nullness of the “I011B” data field. Periodic updates from the B ITRs (or QVDs) Completions Database System are needed to keep this feature up-to-date.

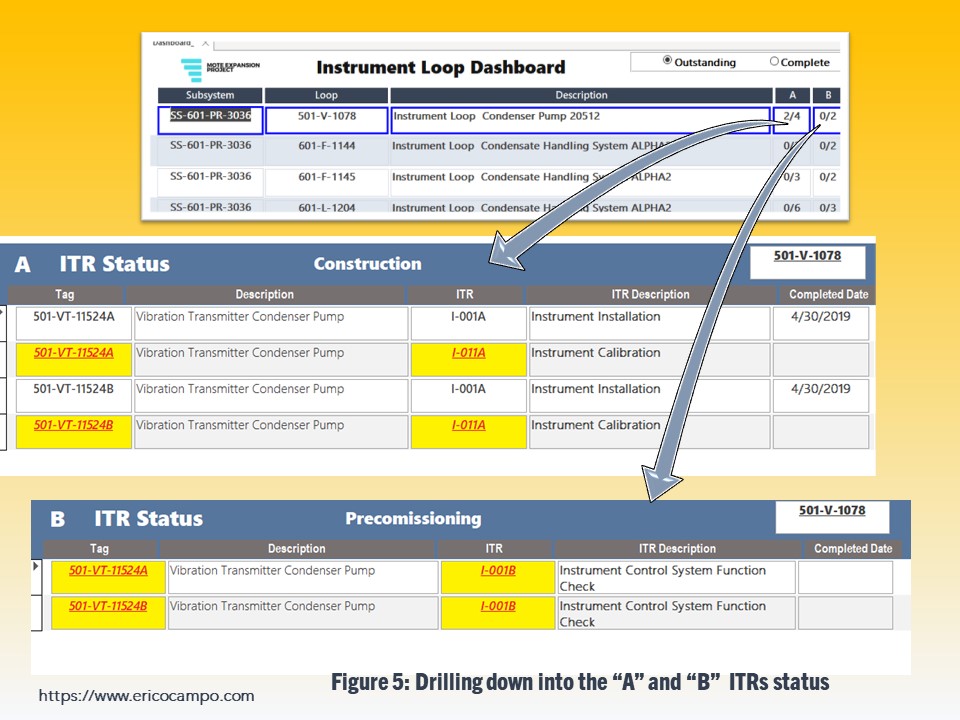

The ITR Completions updates also serve the dashboard to display the quantified completion “A” and “B” ITR status per Loop.

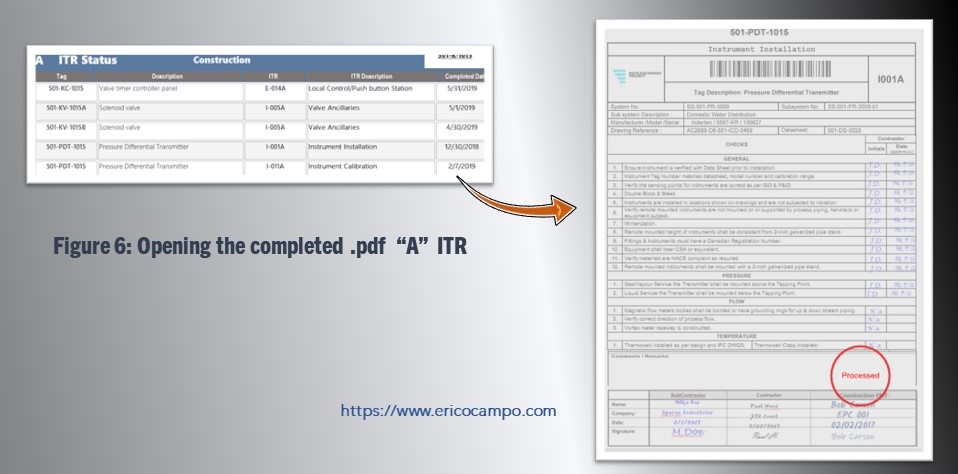

In most of the project “Completions database Systems,” we can bulk-download hundreds of completed ITRs in .pdf format in just a matter of seconds or minutes. They are automatically filenamed using the attributes of each of the Tag-ITR, like Tag, ITR code, barcode, etc.

A simple example is: 501-PDT-4051_I001A.pdf

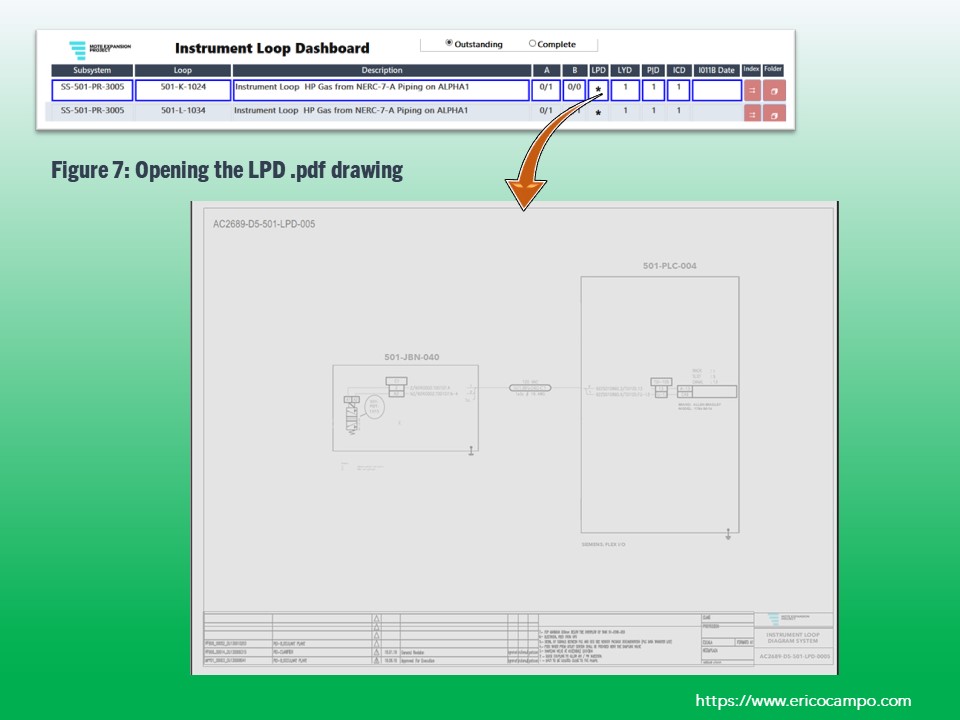

Opening the .pdf files associated to the “Instrument Loop”

The filename criteria should be used into an “open file” button vb script.

Below is part 1 of a short demo video.

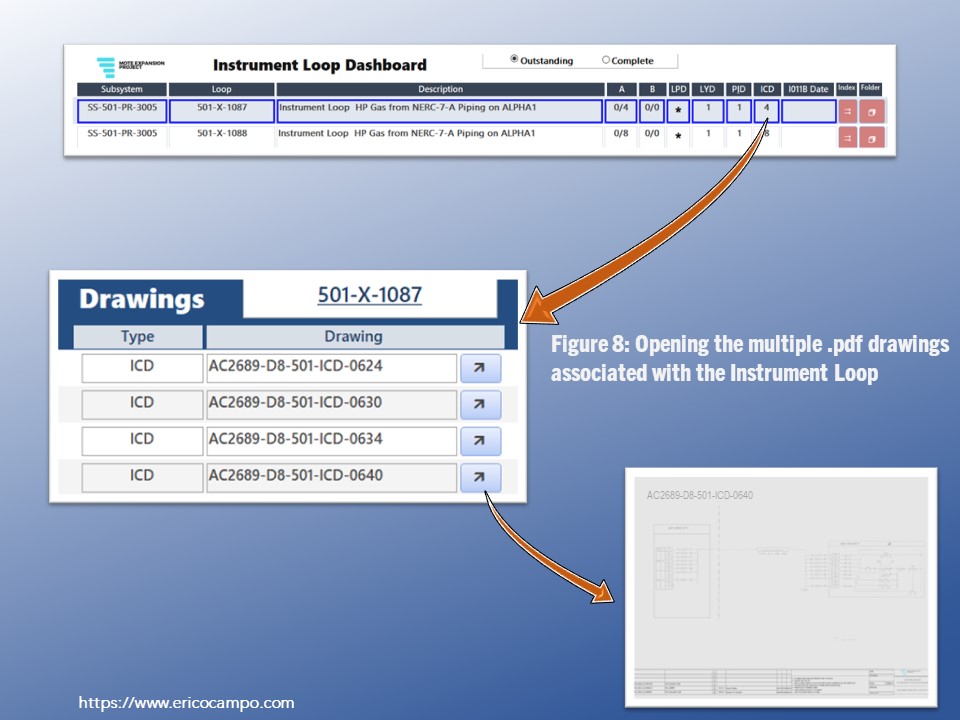

The same applies to the rest of the Instrument Loop documents; first, it is to identify their filename criteria and then to configure “open-file “buttons.

A pop-up list appears for those instrument loops with multiple documents of the same type (i.e., ICD).

And the same will apply for the rest of the documents:

Loop Diagram filename example : AC2689-D5-501-LPD-0001

Data Sheet filename example: AC2689-D7-DS-501-PDT-1001

P & ID filename example: AC2689-D1-501-PID-0001

Interconnection Diagram filename example: AC2689-D8-501-ICD-0050

Layout Drawing (LYD) filename example: AC2689-D6-501-LYD-0006

Below is part 2 of the demo video.

Conclusions

Instrument loop testing is a critical and mandatory process during the precomissioning phase before the start of Commissioning. Each instrument loop test verifies the correct installation, performance, and communication to the Control System (DCS or PLC).

Before loop testing, the instrument pre-commissioning team compiles required documentation into “Instrument Loop folders”.

Like other data-file management processes in EPC projects, I’ve found MS Access a more convenient and powerful tool than spreadsheets. A customized and dynamic dashboard automates several functions and aids in compilation reducing brain focus dispersion for the personnel.

In a future LinkedIn article, I will discuss other buttons and functionalities within the dashboard to facilitate the generation of the cover, index, and the actual location to create the “instrument Loop folder” hardcopy version.

Autumn 2021, I’ve just finished my project assignment in Elkford, the “Wildlife Capital of BC.” Beautiful landscapes along the Crowsnest pass.

Thanks for your feedback and comments on my previous LinkedIn article: “Five Useful Summary Reports and Two Charts in EPC Projects (Completions and Turnover)” , I do welcome them.

If you enjoyed this LinkedIn article, feel free to comment, like, or share it.

Thank you!

Eric Ocampo

ericocampo@ericocampo.com

Eric Ocampo is a Project Management Professional and Microsoft Access Certified Specialist with an Electronic Sciences Degree. He is a proactive Database Administrator/Developer that has worked in Construction, Oil & Gas projects in North and South America, and the Middle East since 2001. He has worked in Mechanical Completions as System Completions Database Administrator (SCDBA) using GoCompletions, MCPlus, Smart Completions Hexagon and WinPCs, and as a Database Developer, he has developed applications for Project Turnover, Completions, Materials, Preservation, Dossier reviews, Weld Tracking, Instrument loops, etc.

His early experience includes a role as MWD (Measure While Drilling) Operator with Anadrill Schlumberger.