“Part of courage is simple consistency” .Peggy Noonan (Journalist)

This article was originally published on LinkedIn, July 7th 2020.

Introduction

System Registers are a key element to achieve an effective and systematic completions, turnover and commissioning of EPCC projects. Company or Project procedures might clearly define tables with criteria, codes and mnemonics for the areas, product, utility type, etc. Nevertheless, very few times they mention “how” to track and administrate a “Master System Register”. (“System” or “Subystem” scope definitions may vary in each project, in the present post I prefer the use of “System”, but “system” and “subsystem” are used invariably in the images and videos of this post)

Project / Company procedures seldom describe “how” to track and administrate a “Master System Register”

As a Project Turnover and Completions Database Administrator, I always prefer the use of MS Access over spreadsheets. Over time I have developed my own MS Access – SQL- VBA applications to complement and empower my administration responsibilities of any Completions platform that the project use. In this post I’m presenting how projects could benefit with a “Master System Register” application.

The creation of the “System List”

The creation of the “system list” follows almost the same pattern: it initially starts as a brainstorm, with battery limits and markups in the early FEED drawings, descriptions here and there of the main process and utility subsystems and a brief idea of the code structure defined by the project and/or company procedures.

Most of the time, unformatted spreadsheets are used with some fields defined. Nevertheless, once the list has gained some consistency, it is time to secure and consolidate it into a dynamic, reliable, and comprehensive “Master Register”. This register will be THE SOURCE visible for everybody in the project and should be easy to edit-and-update for the authorized subsystem creators (Completions or Commissioning Team).

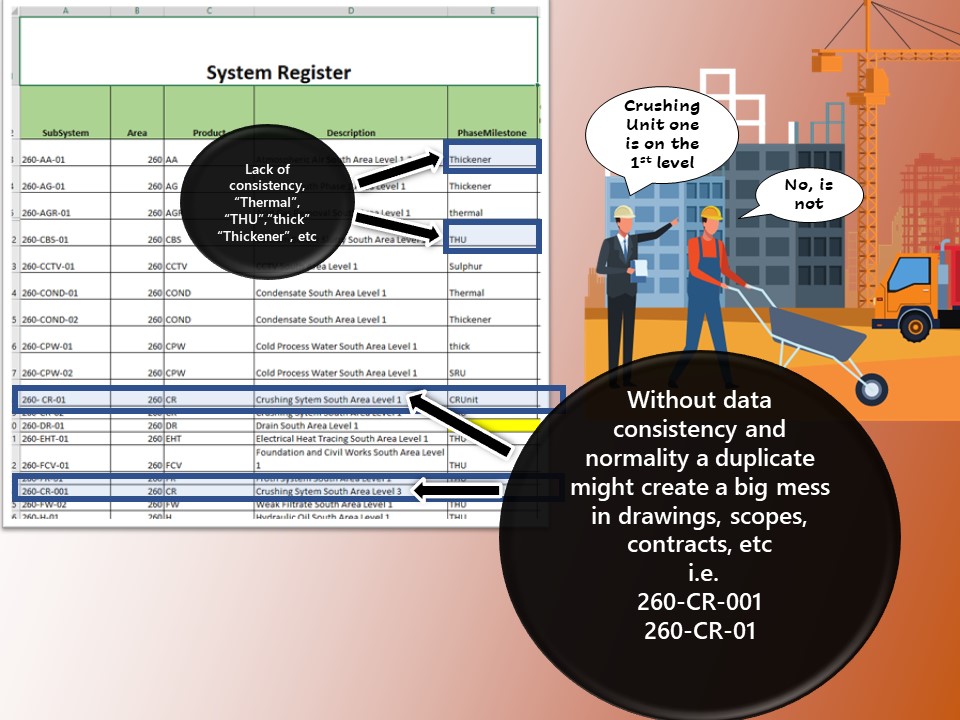

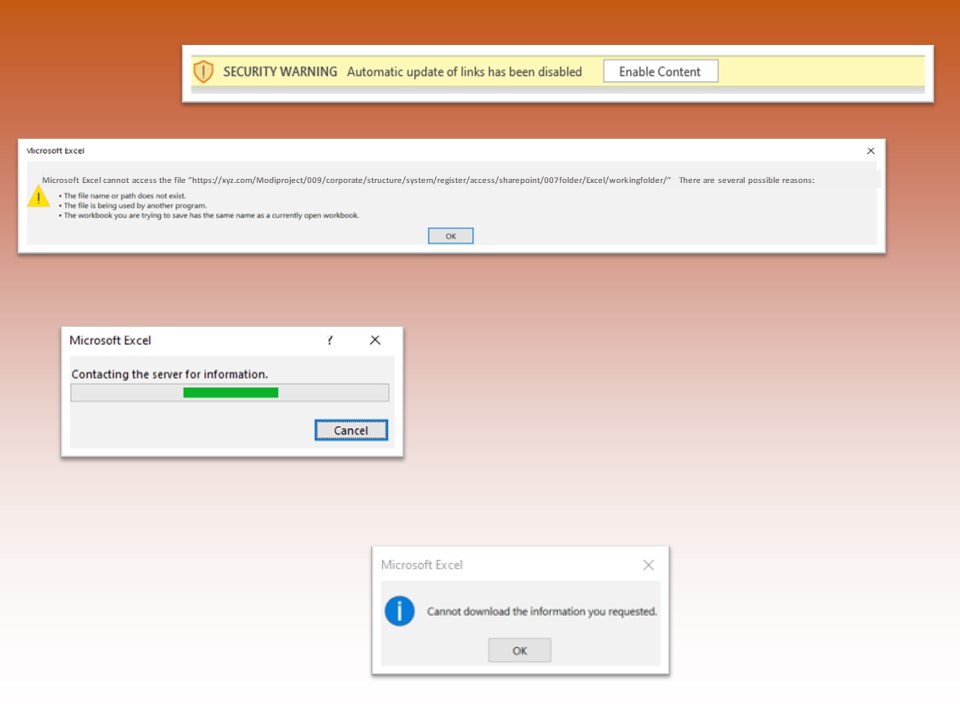

The least anybody wants to encounter in a project is duplicate subsystems, inaccessibility to the information, slow spreadsheets with countless right-scrolling columns, data inaccuracy and to say it plainly in database terms: lack of normalization.

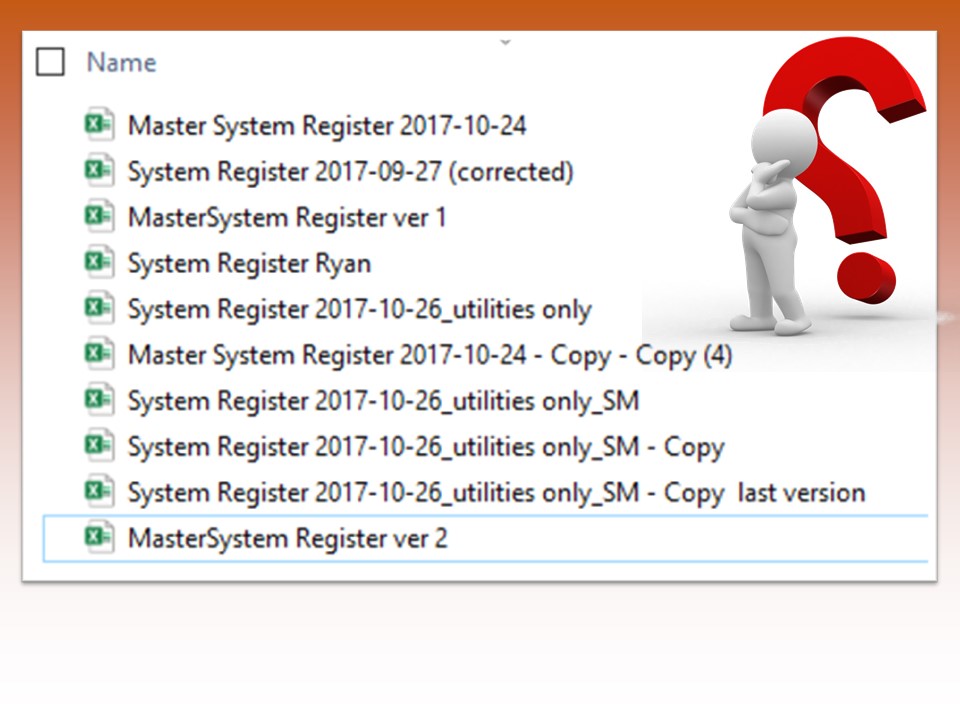

Another distracting, time-consuming, and undesirable situation is a myriad of uncontrolled spreadsheet versions that makes it hard to identify which is the valid one.

An effective approach

A good project approach should result in a “Master System Register” which is more than a simple list but an effective tool to facilitate:

- Information of the drawings in each subsystem (and access to them as shown below in “Video 002”)

- Subsystem information (Schedule dates, champions, groups, types, etc.)

- A quick and reliable exchange of information with the Planning team to ensure schedule consistency by subsystem.

- Quick visibility and download of the latest System list by any person, anytime. Power Application could facilitate it in mobile devices, but I will discuss it in a future post.

- Quick group/sort visibility of subsystems by phase, type of subsystem (process, utility, power, safety, etc.), by fishbone, milestone, priority, etc.

- Edits, updates, and customization per the project requirements.

Video (Master System Register 001

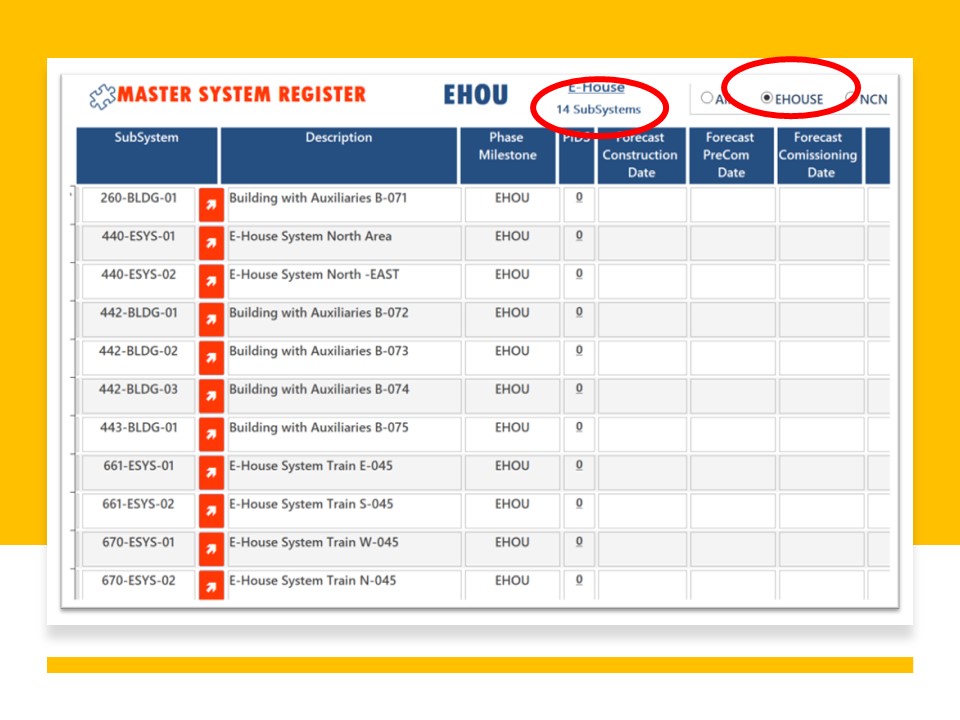

I’ve developed “Master System Register” (MRS) in MS Access as a front-end and back-ended in SQL Server but, could also be deployed in a LAN.

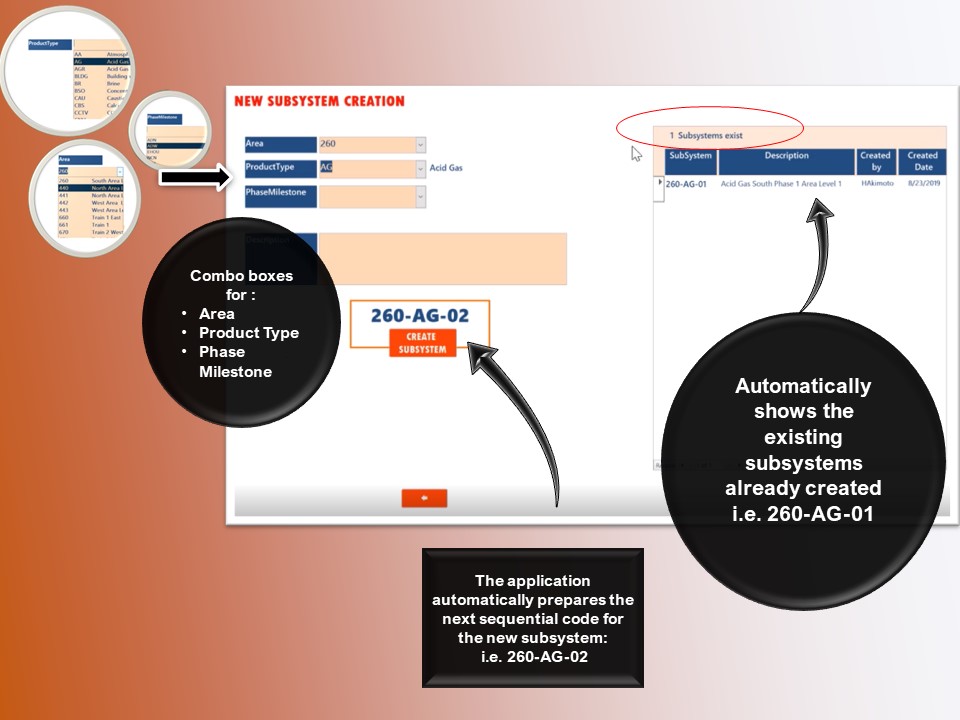

Every time a new subsystem is created in the MRS, the below actions occur:

- Automatically shows the current list of subsystems loaded in that area and system type.

- Automatically create the next sequential code, based on what has previously been created by any other project members.

- Automatically ensures unicity (no duplication)

- Automatically ensures code structure consistency

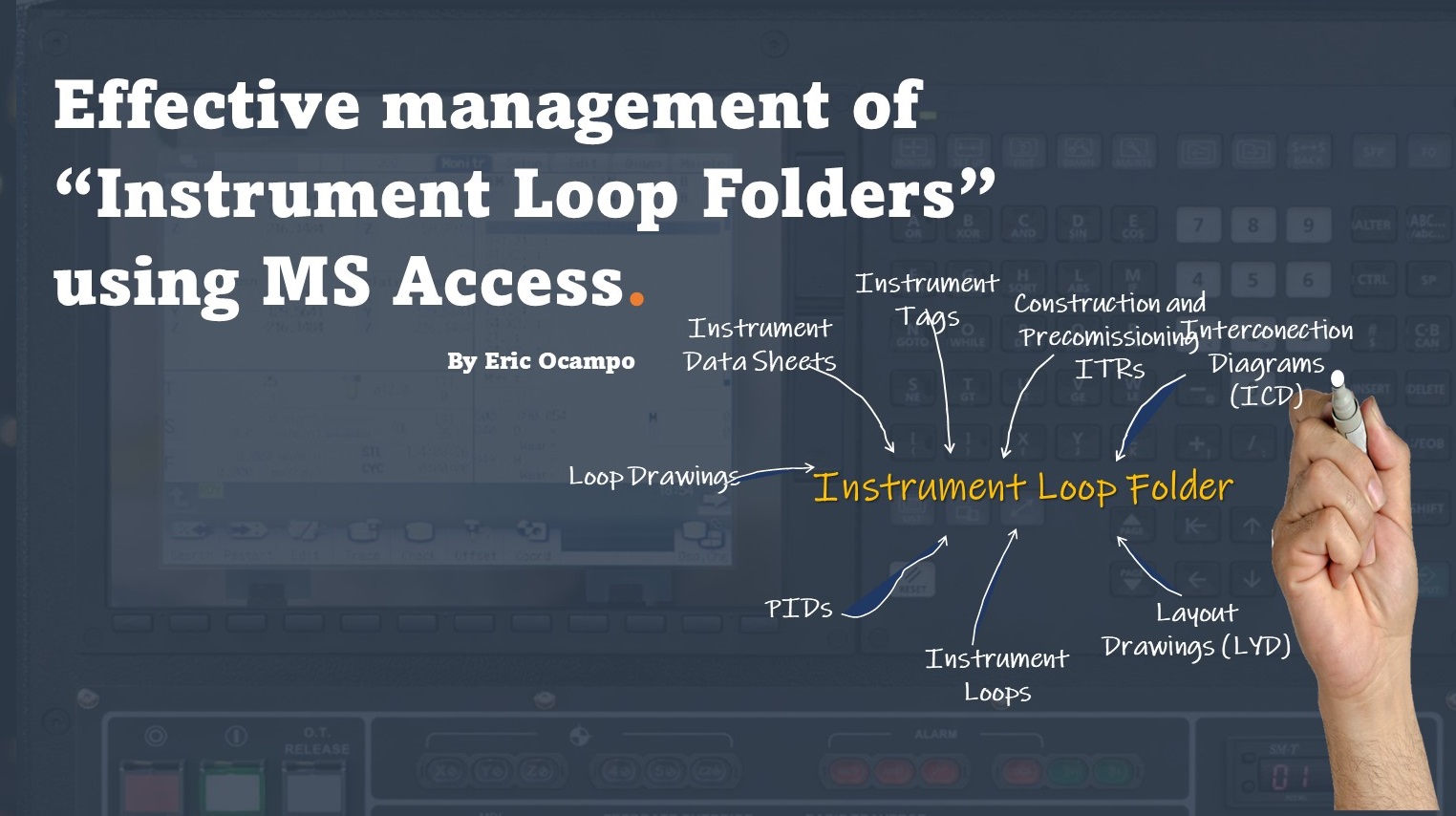

Drawings links to system and hyperlinks to PDF

Here below is a demo of how quickly we can associate and link the PIDs to a subsystem when creating.

Video 002.- Demo of how quickly link the System with their PIDs

Video 003 .- Demo of a quick search

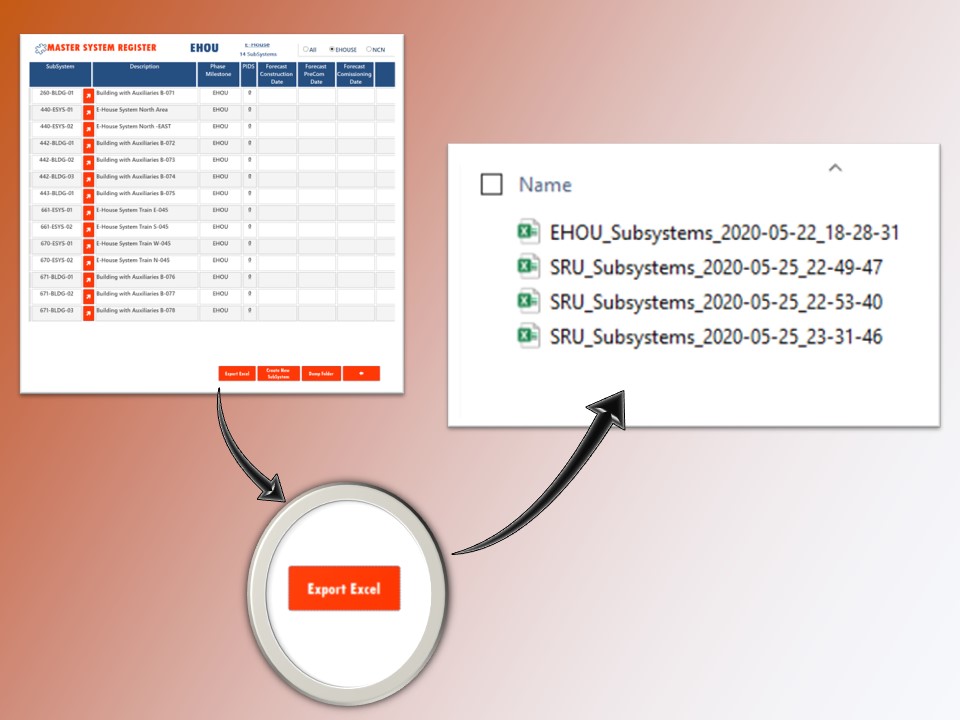

Exporting to a spreadsheet

Yes, I know spreadsheets are universally used to exchange list-type information. So, an export-to-excel button fits this need and purpose. (See how it works in video 001 above)

Conclusions

A good “Master System Register” application should go beyond of mere system spreadsheet. It should automatically assist and provide “data normalization” to the System coding as stated in the narrative of the Company procedure, it should also facilitate a secure and dynamic access, exchange, creation and updates to the systems of the project.

A good “Master System Register” application should go beyond a mere spreadsheet

A dynamic link to the marked-up drawings will indeed benefit people in the project and will save time during System walkdowns, or to identify and reflect unexpected scope changes in mark-up drawings.

A dynamic link to the PIDs will indeed save time to locate drawings when preparing for “System walkdowns”

As I stated at the beginning of the current article, whenever possible I prefer an MS Access application to securely administrate data. Certainly, and most of the time, I have had to tweak a little bit some of the fields and features in my MS-application to meet project data conditions.

It’s been so long since I published my last article, I’ve been so busy in a Mining project in Chile the last 2 years but my assignment just finished last month and am open to new opportunities.

A future article I’m working on is about how projects could better manage the Distribution-Review-Traceability and Turnover of CRP (Construction Release Packages).

COVID 19 has impacted our world and our life in every single aspect, the current situation is a challenge not only for the governments but for society to overcome this pandemic.

StaySafe!

Thanks for your feedback and comments to my previous post-articles, I certainly welcome them.

If you enjoyed this post-article-demo, feel free to comment, like or share it.

Thank you!

Eric Ocampo

ericocampo@ericocampo.com

Eric Ocampo is a Project Management Professional and Microsoft Access Certified Specialist with an Electronic Sciences Degree. He is a proactive Database Administrator/Developer that has worked in Construction, Oil & Gas projects in North and South America, and the Middle East since 2001. He has worked in Mechanical Completions as System Completions Database Administrator (SCDBA) using GoCompletions, MCPlus, Smart Completions Hexagon and WinPCs, and as a Database Developer, he has developed applications for Project Turnover, Completions, Materials, Preservation, Dossier reviews, Weld Tracking, Instrument loops, etc.

His early experience includes a role as MWD (Measure While Drilling) Operator with Anadrill Schlumberger.